PRODUCT LIST

Contact us

VTZ-40.5 Indoor High Voltage Vacuum Circuit Breaker

1.General Description

VTZ-40.5 Indoor High Voltage Vacuum Circuit Breaker is equipped with 与KYN61-40.5(Z)switchgear.It is the newest 40.5KV supply and distribution equipment which is in accordance with GB1984-2003.

2.Applying conditions:

Ambient temperature;-10℃----+40℃

Relative humidity:daily average ≤95%,monthly average ≤90%

Seismic intensity :≤8

Saturated vapor pressure:daily average ≤2.2kPa,monthly average≤1.8kPa;

Altitude:≤1000m;(Not including special requirement)

Service environment:should be avoided fire, explosion risk, serious pollution, chemical corrosion and violent vibration

3. Structural characteristics:

The circuit breaker is consisted of embedded pole and modularized mechanism.It is totally different from opening vacuum circuit breaker and insulating

cylinder circuit breaker.1.Using epoxy resin to enclose vacuum arc-extinguishing

chamber and conductive circuit connector into embedded pole by special process.2.The pole is assembled with modularized mechanism to constitute circuit breaker.3.Own excellent mechanical and electrical property.

VTZ-40.5 embedded pole’s design fully consider the requirement of domestic and oversea market.Utilizing solid insulating advantage and APG process to

integrate vacuum arc-extinguishing chamber,conductive circuit connector and insulating support into embedded pole.This process not only simplify embedded pole’s assembly to avoid connecting bolt looseness of conductive circuit into vacuum arc-extinguishing chamber resulting of run shake,but also enhance reliability to avoid surface influence of vacuum arc-extinguishing chamber being from

outer mechanical force and environment (such as dust,humidity,filthy,high altitude and animal.,etc).Meanwhile,it avoids surface flashover fault which is occurred

under opening status in VCB,due to outer insulation in vacuum arc-extinguishing chamber is worked in bad work condition that lead to reduce insulating level.Thus,Embedded pole during mechanical life is totally free maintenance.Meanwhile,key point is that solid insulation replace of the need of SF6 as outer insulation.That mean that it is more pro-environment.

4.Technical specification

No. | Item | Unit | Data | ||

1 | Rated voltage | kV | 40.5 | ||

2 | Rated power frequency withstand voltage/1min | kV | 95 | ||

3 | Rated lighting impulse withstand voltage | kV | 185 | ||

4 | Rated frequency | Hz | 50/60 | ||

5 | Rated current | A | 1250 | 1600 | 2000 |

6 | Rated short circuit breaking current | kA | 25/31.5 | 25/31.5 | 31.5 |

7 | Rated withstand current(peak) | kA | 63/80 | 63/80 | 80 |

8 | Rated duration of short circuit | s | 4 | ||

9 | Rated operating sequence | O—0.3s—CO—180s—CO | |||

10 | Closing time | ms | 50~100 | ||

11 | Opening time | ms | 30~60 | ||

12 | Circuit resistance | μΩ | ≤60;≤80(Rated current 1250A) | ||

13 | Rated short circuit breaking times | Times | 20 | ||

14 | Rated operating Voltage | V | —110/~110,—220/~220 | ||

15 | Rated current of closing &opening coil | A | 1.05/(—110V);0.96/(—220V) | ||

16 | Mechanical life | Times | 10000 | ||

17 | Operating mechanism | 3AV3 Special spring mechanism | |||

18 | Max DC component | 40% | |||

19 | Rated single capacitor bank breaking current | A | 400 | ||

20 | Rated back to back capacitor bank breaking current | A | 400 | ||

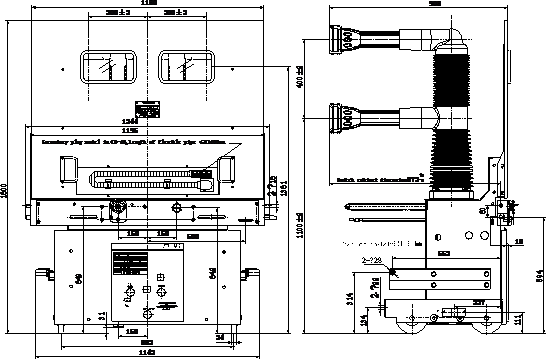

5.Overall drawing

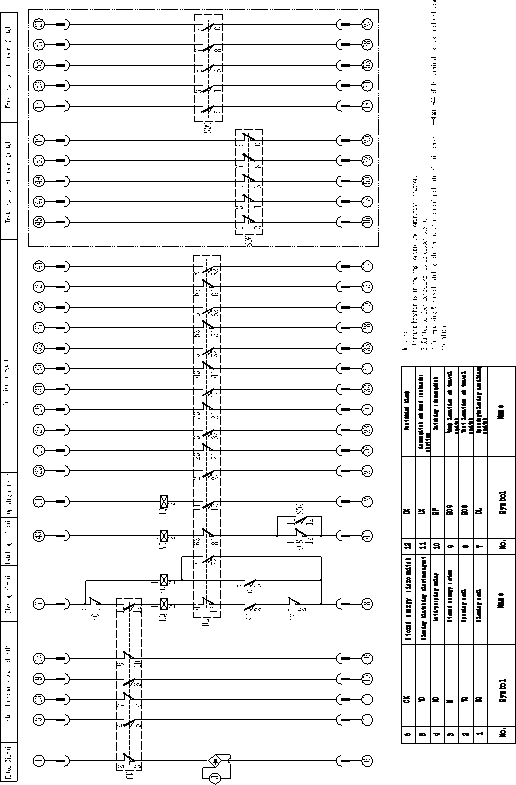

6. Secondary connection diagram